लोगो मुद्रण स्विमवियर बनाने के लिए अधिक लागत बनाता है। निर्माताओं को बिकिनी और एक-टुकड़ा स्विमसूट पर लोगो को प्रिंट करने के लिए अधिक कदम, सामग्री और काम की आवश्यकता होती है। स्विमवियर बनाना विभिन्न मुद्रण विधियों का उपयोग करता है। प्रत्येक विधि बिकनी और एक-टुकड़ा सूट की अंतिम कीमत बदलती है। आदेश का आकार और जहां इसे बनाया जाता है, लागत भी बदल देता है। ब्रांडों को देना चाहिएलोगो फ़ाइलें और नमूनेकस्टम स्विमवियर निर्माता जल्दी से। यह निर्माता को ब्रांड के लुक और गुणवत्ता की जरूरतों को जानने में मदद करता है। अच्छा संचार आश्चर्य को रोकता है और स्विमवियर लागत स्थिर रखता है।

प्रमुख टेकवे

लोगो प्रिंटिंग को अधिक चरणों और सामग्रियों की आवश्यकता होती है, इसलिए स्विमवियर बनाने में अधिक खर्च होता है। प्रिंट करने के अलग-अलग तरीके, जैसे स्क्रीन प्रिंटिंग, डिजिटल प्रिंटिंग, कढ़ाई और सबलिमिनेशन, कीमत, गुणवत्ता और आपको कितने ऑर्डर करने की आवश्यकता है। यदि आप एक बार में बहुत ऑर्डर करते हैं, तो प्रत्येक स्विमसूट की लागत कम है क्योंकि सेटअप और सामग्री साझा की जाती है। कई रंगों के साथ सरल लोगो सस्ता नहीं है और तेजी से प्रिंट करते हैं, इसलिए ब्रांड पैसे बचा सकते हैं। एक अच्छा निर्माता चुनना और स्पष्ट लोगो फ़ाइलों को जल्दी देने में मदद करता हैअच्छी गुणवत्ताऔर कीमतों को स्थिर रखता है।

छपाई के तरीके

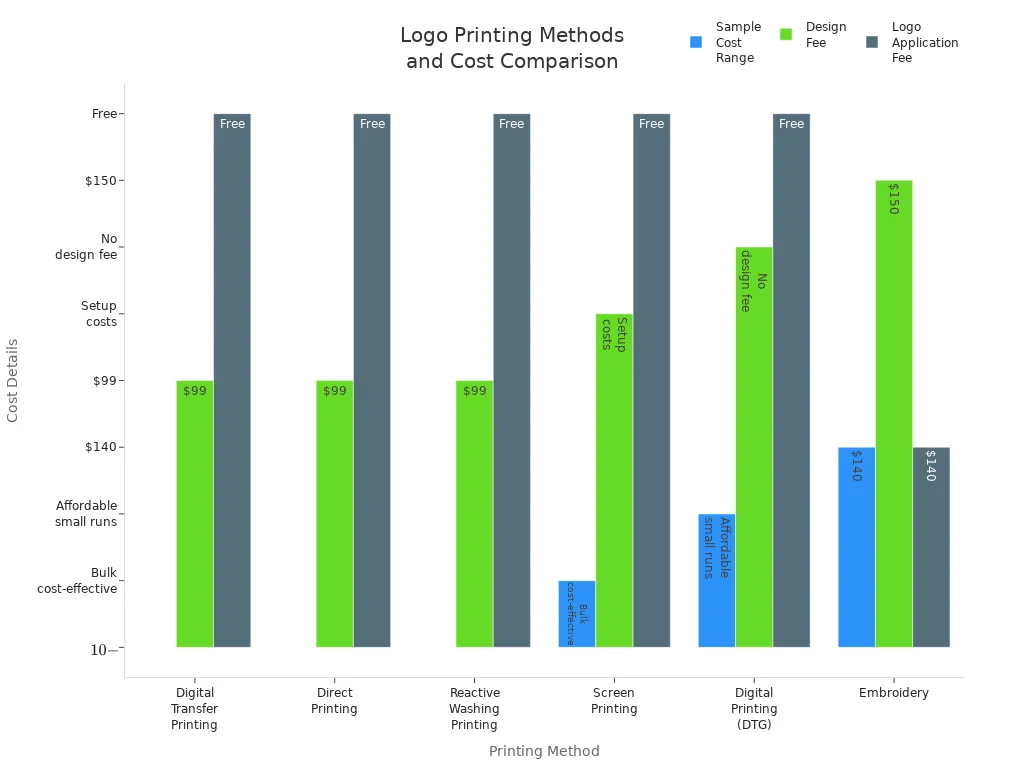

कस्टम स्विमवियर निर्माता लोगो को स्विमवियर पर लगाने के लिए अलग-अलग तरीकों का उपयोग करते हैं। हर तरह से बदलता है कितना खर्च यह भी प्रभावित करता है कि यह कब तक रहता है और यह कैसे दिखता है।

स्क्रीन प्रिंटिंग

स्क्रीन प्रिंटिंग लोगो को प्रिंट करने का एक सामान्य तरीका है। निर्माताओं को प्रत्येक रंग के लिए एक स्क्रीन की आवश्यकता होती है। यह सेटअप अधिक महंगा है। स्क्रीन प्रिंटिंग ठोस रंगों के साथ सरल लोगो के लिए सबसे अच्छा काम करता है। यह उज्ज्वल रंग देता है और मध्यम अवधि तक रहता है। यदि आप बहुत कुछ ऑर्डर करते हैं, तो प्रत्येक टुकड़े की कीमत कम हो जाती है। लेकिन आपको कम से कम टुकड़ों का ऑर्डर करना होगा। यदि आप रंग बदलना चाहते हैं या नई कलाकृति तैयार करना चाहते हैं। स्क्रीन प्रिंटिंग नायलॉन और पॉलिएस्टर पर अच्छी तरह से काम करती है। लेकिन प्रिंट क्रैक कर सकते हैं यदि स्विमवियर बहुत अधिक फैला है।

लागत घटक | वर्णन | लागत/विवरण |

|---|---|---|

स्क्रीन की लागत | प्रत्येक रंग के लिए एक स्क्रीन | |

नमूना प्रभार | छोटे आदेशों के लिए अतिरिक्त शुल्क | अधिक शुल्क |

प्री-प्रोडक्शन के नमूने | रंग द्वारा नमूना प्रिंट के लिए लागत | $25-$150 प्रति रंग |

स्याही परिवर्तन | विशेष स्याही के लिए अतिरिक्त लागत | $12-$20 प्रति परिवर्तन |

कलाकृति की तैयारी | डिजाइन तैयार करने का समय | $50-$60 प्रति घंटे |

डिजिटल प्रिंटिंग

डिजिटल प्रिंटिंग का उपयोगपानी आधारित स्याहीलोगो के लिए। यह कई रंगों और विस्तृत डिजाइनों को प्रिंट कर सकता है। यह तरीका छोटे आदेशों के लिए बेहतर है क्योंकि सेटअप लागत कम है। वहाँ हैन्यूनतम आदेश नहींजरूरत है। डिजिटल प्रिंटिंग कपास मिश्रण पर सबसे अच्छा काम करता है। यह सिंथेटिक स्विमवियर पर भी काम नहीं करता है। केप्रत्येक टुकड़े की कीमत अधिक हैयदि आप बहुत कुछ ऑर्डर करते हैं। इसलिए, यह बड़े आदेशों के लिए सबसे अच्छा विकल्प नहीं है। डिजिटल प्रिंटिंग तेजी से है और ब्रांडों को समय और पैसा बचाने में मदद करता है।

टिप: डिजिटल प्रिंटिंग ब्रांड नए डिजाइन जल्दी से नए डिजाइन का प्रयास करें। यह कचरे को कम करने में मदद करता है। लेकिन यह अन्य तरीकों से लंबे समय तक नहीं रह सकता है।

कढ़ाई

कढ़ाई का अर्थ है स्विमवियर में सिलाई करना निर्माता टांके या पैच का उपयोग करते हैं। इसकी लागत अधिक है क्योंकि यह अतिरिक्त काम और विशेष मशीनों की आवश्यकता होती है। कढ़ाई लंबे समय तक रहती है और फैंसी लग रही है। यह प्रत्येक लोगो के लिए $140 तक खर्च कर सकता है। यह लोगो को जोड़ने के सबसे महंगे तरीकों में से एक बनाता है। कढ़ाई उन ब्रांडों के लिए अच्छा है जो लक्जरी स्विमवियर चाहते हैं।

अवदान

स्लिमिनेशन प्रिंटिंग लोगो को उज्ज्वल और लंबे समय तक चलने वाले बनाने के लिए डाई का उपयोग किया जाता है। लोगोस क्रैक, छिलके या फीका नहीं है। इस तरह के लिए विशेष प्रिंटर और हीट प्रेस की आवश्यकता होती है। इन मशीनोंपहले बहुत महंगा. आपको स्याही और पेपर रिफिल भी खरीदना होगा। पॉलिएस्टर स्विमवियर पर सबसे अच्छा काम करता है। यह आपको पूरे कपड़े पर प्रिंट करने देता है। हर टुकड़े की कीमत$5 से $9 यदि आप थोक में ऑर्डर करते हैं. आपको कम से कम 20 टुकड़ों का ऑर्डर करना होगा। Uv सुरक्षा और खिंचाव की लागत अधिक है।

मुद्रण विधि | विवरण/नोट्स | लागत विवरण/मूल्य निर्धारण उदाहरण |

|---|---|---|

स्क्रीन प्रिंटिंग | ठोस रंगों के लिए अच्छा, आवश्यक सेटअप | थोक के लिए सस्ता; सेटअप लागत और न्यूनतम आदेश आवश्यक |

डिजिटल प्रिंटिंग (dtg) | कई रंग, कोई न्यूनतम आदेश नहीं | छोटे आदेशों के लिए सस्ता; पानी आधारित स्याही; धीमी उत्पादन |

कढ़ाई | फैंसी ब्रांडिंग, पैच या प्रत्यक्ष सिलाई | लोगो: $140 (मार एयू मोडा प्रेसा)मुद्रित लोगो मुक्त |

अवदान | उज्ज्वल, मजबूत प्रिंट; पर्यावरण के अनुकूल सामग्री | $5-$9 प्रति टुकड़ा (थोक); उच्च उपकरण लागत |

निर्माताओं का चयनछपाई के तरीकेलोगो विवरण, ऑर्डर आकार और कब तक चलेगा डिजिटल प्रिंटिंग तेज और लचीला है। स्क्रीन प्रिंटिंग और सबलिमिनेशन बड़े ऑर्डर के लिए सस्ते हैं। कढ़ाई फैंसी लग रही है, लेकिन लागत अधिक है।

लागत कारक

सेटअप शुल्क

सेटअप शुल्कवे स्विमवियर बनाने का एक बड़ा हिस्सा हैं। प्रत्येक मुद्रण विधि को शुरू करने से पहले विशेष चरणों की आवश्यकता होती है। स्क्रीन प्रिंटिंग के लिए, प्रत्येक रंग के लिए एक नई स्क्रीन की आवश्यकता होती है। इसमें अतिरिक्त समय और पैसा लगता है। डिजिटल प्रिंटिंग और सबलिमिनेशन की आवश्यकता कम होती है। लेकिन मशीनों को अभी भी सेट और परीक्षण करने की आवश्यकता है। कढ़ाई सेटअप का अर्थ होता है प्रोग्रामिंग मशीन और परीक्षण टांके. यह शुल्क तब जाता है जब लॉगोस बिकनी और एक-टुकड़े दोनों पर हैं। स्थापना लागत भी लोगो विवरण और रंग संख्या के साथ बदल जाती है। विभिन्न स्थानों पर श्रम और उपकरणों की लागत के कारण अलग-अलग शुल्क लेते हैं।

सामग्री और स्याही

सामग्री और स्याही बदलते हैं कि स्विमवियर कैसे दिखते हैं और लागत. अधिकांश स्विमवियर का उपयोग करता है जैसेपॉलीमाइड लाइक्ररा या पॉलिएस्टर. पॉलीमाइड लाइक्रा एसिड के साथ सबसे अच्छा काम करता है। ये स्याही रंगों को उज्ज्वल और अंतिम बनाते हैं। पॉलिएस्टर मिश्रण उन सबलिमिनेशन स्याही का उपयोग करते हैं जो कपड़े में गहरे जाते हैं। ये सामग्री पर्यावरण के अनुकूल हैं और लंबे समय तक रहते हैं। पॉलिएस्टर पर सबलिमिनेशन प्रिंटिंग को विशेष मशीनों की आवश्यकता होती है। यह अधिक महंगा है, लेकिन अतिरिक्त धोने को छोड़ देता है। डिजिटल कपड़ा मुद्रण पानी आधारित स्याही का उपयोग करता है। ये लिंक बेहतर प्रिंट और तेजी से काम करते हैं। स्याही प्रकार इस बात के लिए मायने रखता है कि लोग कितने लंबे समय तक रहते हैं और वे कैसे दिखते हैं। अच्छी स्याही की लागत अधिक है, लेकिन लोगो को बिकिनी और एक-टुकड़े पर तेज रखें।

कपड़े का प्रकार | रचना | स्याही प्रकार |

|---|---|---|

लिक्रा मैट | 90% पॉलिएस्टर/10% लिक्रा | सबलिमिनेशन डाई |

लिक्रा नरम शीन | 85% पॉलिएस्टर/15% इलास्टेन | सबलिमिनेशन डाई |

स्लिंकी लाइक्ररा मैट | 82% पॉलिएस्टर/18% लिक्रा | सबलिमिनेशन डाई |

फ्लेक्स खेल लाइक्रा | 80% पॉलिएस्टर/20% इलास्टेन | सबलिमिनेशन डाई |

नोटः गर्मी-फिक्सिंग के साथ पानी-आधारित और पर्यावरण के अनुकूल स्याही स्विमवियर का उपयोग करने पर लोगो को छीलने या खरोंच से रोकने में मदद करते हैं।

श्रम लागत

श्रम लागतस्विमवियर की कुल कीमत में जोड़ें। श्रमिक कपड़े से लेकर मुद्रण और परिष्करण तक हर कदम करते हैं। स्क्रीन प्रिंटिंग और कशीदाकारी को सेटअप और जांच के लिए कुशल श्रमिकों की आवश्यकता होती है। डिजिटल प्रिंटिंग और सबलिमिनेशन अधिक मशीनों का उपयोग करते हैं। लेकिन लोग अभी भी अच्छी गुणवत्ता की जांच करते हैं। देश में श्रम की लागत बदलती है। उच्च वेतन वाले स्थानों पर कारखाने अधिक शुल्क लेते हैं। बिकनी और एक-टुकड़े पर कठोर लोगो को अधिक समय लगता है। इससे श्रम लागत बढ़ जाती है।

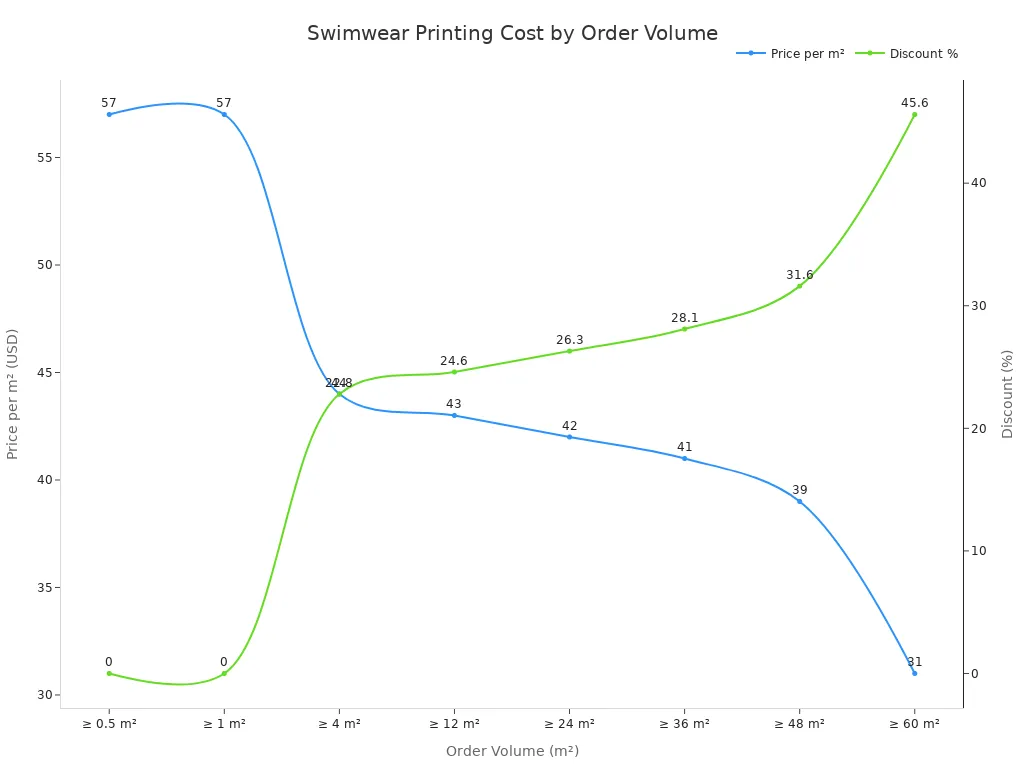

आदेश आकार

ऑर्डर आकार प्रत्येक टुकड़े के लिए लागत बदल देता है। बड़े आदेश प्रत्येक बिकनी या एक-टुकड़ा सस्ता बनाते हैं। ऐसा इसलिए है क्योंकि सेटअप और सामग्री की लागत फैली हुई है। उदाहरण के लिए, एक200-टुकड़ा ऑर्डर $18 से $20 प्रति आइटम. लोगो प्रिंटिंग या कढ़ाई जोड़ना $1 से $2 प्रति टुकड़ा जोड़ता है। प्रत्येक आइटम के लिए छोटे ऑर्डर की लागत अधिक है। ऐसा इसलिए है क्योंकि सेटअप शुल्क और कचरा नहीं फैलता है। बड़े आदेशों को अधिक छूट मिलती है। थोक स्विमवियर पैसा बचाता है।

प्रति वर्ग मीटर (यूएसडी) | छूट (%) | |

|---|---|---|

0.5 | 57 | 0 |

° 4 | 44 | 22.8 |

° 24 | 42 | 26.3 |

° 60 | 31 | 45.6 |

गुणवत्ता नियंत्रण

गुणवत्ता नियंत्रण सुनिश्चित करता है कि प्रत्येक बिकनी और एक-टुकड़ा अच्छा है। निर्माता स्पष्ट लोगो, यहां तक कि रंग और मजबूत टांके की जांच करते हैं। उच्च-रिज़ॉल्यूशन लोगो फ़ाइलों को निशान और पेशेवर रखता है. कम-रिज़ॉल्यूशन छवियां लोगो को धुंधला और कम गुणवत्ता बनाती हैं। प्रिंटर लोगो विवरण के लिए विभिन्न dpi सेटिंग्स का उपयोग करते हैं। उच्च डीपीआई बेहतर गुणवत्ता प्रदान करता है, लेकिन अधिक स्याही का उपयोग करता है और काम करता है।. इससे लागत बढ़ जाती है। कम डीपीआई सरल लोगो और बड़े आदेशों के लिए अच्छा है। यह समय और पैसा बचाता है। गुणवत्ता नियंत्रण रंग और कपड़े की ताकत की भी जांच करता है। यह स्विमवियर कई उपयोगों के माध्यम से अंतिम रूप से मदद करता है।

टिप: ब्रांडों को हमेशा कस्टम स्विमवियर निर्माता को उच्च-रिज़ॉल्यूशन लोगो फ़ाइलें देनी चाहिए। यह अतिरिक्त लागत से बचने में मदद करता है और उत्पाद को तेज दिखता है।

मौसमी रुझान और फैशन चक्रगुणवत्ता नियंत्रण और लागत बदलें। वसंत और गर्मियों में स्नान की मांग बढ़ जाती है। इसका मतलब है अधिक लोगो मुद्रण आदेश निर्माताओं को इन रुझानों से मेल खाने के लिए शेड्यूल और स्टॉक को बदलना होगा। तेज शैली और रंग परिवर्तन को त्वरित कार्रवाई की आवश्यकता है. इससे सामग्री और श्रम की लागत बढ़ सकती है। नई तकनीक, स्वचालन की तरह, इन परिवर्तनों के साथ मदद करती है। लेकिन यह लागत अधिक हो सकती है।

स्विमवियर विनिर्माण में लागत की तुलना

लोगो प्रिंटिंग के बिना

लोगो मुद्रण के बिना स्विमवियर बनाना सरल है। कारखाने नियमित कपड़े और बुनियादी असेंबली लाइनों का उपयोग करते हैं। प्रत्येक बिकनी या एक टुकड़ा लागत के बीच$9 और $20. कीमत कपड़े, सिलाई और गुणवत्ता पर निर्भर करती है। उच्च गुणवत्ता वाले स्विमवियर पर्यावरण के अनुकूल सामग्री और मजबूत सीम का उपयोग करता है। ये चीजें लागत अधिक बनाती हैं, लेकिन लंबे समय तक रहती हैं। बड़े आदेशों के लिए, कारखाने कम से कम टुकड़े चाहते हैं। यह सामग्री और श्रम लागत को फैलाने में मदद करता है। ब्रांड पहली इन्वेंट्री और पैकेजिंग के लिए भुगतान करते हैं। बड़े ऑर्डर $100,000 या उससे अधिक खर्च हो सकते हैं। लोगो प्रिंटिंग के बिना, प्रक्रिया तेज और आसान है।

लोगो प्रिंटिंग के साथ

जोड़नालोगो मुद्रणस्विमवियर को और कदम उठाने के लिए। कारखानों में स्क्रीन प्रिंटिंग, कढ़ाई या सबलिमिनेशन के साथ ब्रांडिंग जोड़ते हैं। प्रत्येक तरह से बिकनी और एक-टुकड़े की अंतिम कीमत बदलती है। उदाहरण के लिए, लोगो मुद्रण लागत के साथ 100 टुकड़ेलगभग 1,500 डॉलर. इसमें स्विमवियर के लिए $1,200 और लेबलिंग और पैकेजिंग के लिए $300 शामिल हैं। प्रत्येक बिकनी शीर्ष $12 से शुरू होता है। एक टुकड़े की लागत लगभग $18 है। कस्टम डिज़ाइन शुल्क आमतौर पर प्रति डिजाइन $99 है। कारखाने अक्सर बड़े आदेशों के लिए यह शुल्क वापस देते हैं। नमूना लागत $200 से $2,000 तक जाती है। कीमत डिजाइन और आकार पर निर्भर करती है। शिपिंग प्रत्येक टुकड़े के लिए $1 जोड़ता है। लोगो मुद्रण के लिए उच्च गुणवत्ता वाली फ़ाइलों की आवश्यकता होती है।

लागत घटक | मूल्य सीमा/उदाहरण लागत |

|---|---|

नमूना लागत | $200 से $2,000 |

थोक उत्पादन (बिकनी टॉप) | $12 प्रति टुकड़ा |

थोक उत्पादन (एक टुकड़ा) | $18 प्रति टुकड़ा |

लोगो प्रिंटिंग/लेबलिंग | $300 प्रति 100 टुकड़े |

कस्टम डिजाइन शुल्क | $99 प्रति डिज़ाइन (ऑर्डर करने के लिए क्रेडिट) |

शिपिंग | $1 प्रति टुकड़ा |

100 टुकड़ों के लिए कुल | $1,500 (लोगो मुद्रण सहित) |

नोटः लोगो प्रिंटिंग की लागत सरल ब्रांडिंग के लिए कम रहती है। अधिक विस्तृत लोगो, जैसे कढ़ाई या कई रंगों, अधिक लागत

कीमत अंतर

अधिकांश स्विमवियर ऑर्डर के लिए मूल्य अंतर छोटा है। मानक लोगो प्रिंटिंग जोड़ता है$1 से $2 प्रति बिकनीया एक टुकड़ा. यह आधार मूल्य पर एक छोटी वृद्धि है। लॉगोस के साथ सेट की लागत $18 से $28 है। फैंसी विकल्प, कढ़ाई लोगोस की तरह, कीमत थोड़ी बढ़ जाती है। अधिकांश स्विमवियर के लिए, प्रतिशत की वृद्धि कम है। फैक्ट्रियों का लोगो प्रिंटिंग तेजी से बना हुआ है. ब्रांड को बड़ी कीमत में उछाल के बिना पेशेवर लोगो मिलता है।

उदाहरण:

एक सादे टुकड़े की लागत $18 है।

एक मुद्रित लोगो के साथ एक ही टुकड़ा $19 या $20 ।

कीमत केवल 10% तक 5% जाती है।

टिप: ब्रांड सरल लोगो को चुनकर और अधिक टुकड़ों को ऑर्डर करके पैसे बचा सकते हैं। यह स्विमवियर अच्छा रहता है और कीमतें स्थिर रहती हैं।

कस्टम स्विमवियर निर्माता के लिए लागत प्रबंधन

विधि चयन

ब्रांड सबसे अच्छा लोगो प्रिंटिंग तरीका चुनकर पैसे बचा सकते हैं। उन्हें चाहिएनमूना नियमों के बारे में कस्टम स्विमवियर निर्माता से पूछें. यह उन्हें बड़े ऑर्डर से पहले प्रिंट गुणवत्ता की जांच करने में मदद करता है। स्पष्ट मूल्य और सामग्री ब्रांड अपने बजट की योजना बनाने में मदद करती है। निर्माता के साथ बातचीत अच्छी तरह से चलती रहती है। एक लोगो का विवरण बदलता है जो मुद्रण का तरीका सबसे अच्छा है। कई बिकिनी और एक-टुकड़े के लिए अच्छा है. विस्तृत लोगो के लिए डिजिटल प्रिंटिंग बेहतर है, लेकिन बड़े आदेशों के लिए अधिक लागत है। गर्मी हस्तांतरण मुद्रण पूरे स्विमसूट को कवर करता है। ब्रांडों को कपड़े के बारे में भी सोचने की आवश्यकता है, और यह विभिन्न भागों पर कैसा दिखता है।

नमूना नियमों और प्रिंट गुणवत्ता के बारे में पूछें।

स्पष्ट मूल्य और सामग्री की जाँच करें।

सही मुद्रण तरीके से सही प्रिंटिंग तरीके से मेल खाता है।

कपड़े के बारे में सोचें और कहां जाता है।

डिजाइन सरलीकरण

साधारण लोगो को स्विमवियर पर कम खर्च करने में मदद करते हैं। लोगो में कम रंगों का उपयोग करने से मुद्रण सस्ता हो जाता है. प्रत्येक रंग अधिक लागत जोड़ता है। विशेष प्रिंट का उपयोग न करना कपड़े बचाता है और काम को आसान बनाता है. जहां लोगो चला जाता है और उसका आकार भी पैसा बचाता है। ब्रांड बिकनी और एक-टुकड़े को प्रिंट करने के लिए बहुत कठिन बना सकते हैं, बिना उन्हें प्रिंट करना मुश्किल है। सरल लोगो तेजी से प्रिंट करें और कम सामान का उपयोग करें, इसलिए लागत कम रहती है।

टिप: छोटे बजट वाले ब्रांडों को सरल डिजाइन का उपयोग करना चाहिए। यह उन्हें खरीदारों तक पहुंचने और लागत को कम करने में मदद करता है।

थोक आदेश

बहुत सारे स्विमवेयर खरीदेंहर बार कीमत कम कर देता है। कारखानों ने सेटअप और अधिक बिकनी या एक-टुकड़े पर काम की लागत का विस्तार किया। यह प्रत्येक लागत कम करता है। उदाहरण के लिएः

क्रम आकार सीमा | प्रति इकाई अनुमानित मूल्य (usd) | मूल्य भिन्नता का कारण |

|---|---|---|

$20 - $30 + | अतिरिक्त काम और कपड़े की लागत के कारण छोटे ऑर्डर अधिक लागत | |

300 इकाइयों के आसपास | $9 - $20 | बड़े ऑर्डर की लागत कम है क्योंकि काम तेज और आसान है |

बड़े आदेश कारखानों को एक बार में अधिक कपड़े खरीदने देते हैं, जिससे पैसा बचाता है। प्रत्येक बिकनी या एक-टुकड़ा के लिए अधिक लागत

निर्माता विकल्प

कुशल कस्टम स्विमवियर निर्माता चुनने से ब्रांडों को पैसा बचाने में मदद करता है।. इन निर्माताओं के पास अच्छी आपूर्ति श्रृंखला है और जानते हैं कि लागत को कैसे कम रखा जाए। उनकी टीम ब्रांड को ऑर्डर करने और समस्याओं से बचने में मदद करती है। बहुत सारे अनुभव और मजबूत जांच वाले कर्मचारी गलतियों और कचरे को बंद कर देते हैं। नमूना ब्रांडों को बड़े आदेशों से पहले कपड़े, प्रिंट और फिट देखने की अनुमति देता है। अच्छा प्रबंधन और स्मार्ट खरीदारी कीमतों को कम करता है। एक अच्छा निर्माता के पास कई प्रिंटिंग विकल्प हैं। यह ब्रांड बिकिनी और एक-टुकड़े में लोगो को जोड़ने का सबसे सस्ता तरीका चुनने देता है।

नोटः सही निर्माता ब्रांड प्रत्येक स्विमवियर ऑर्डर के लिए लागत और गुणवत्ता दोनों को नियंत्रित करने में मदद करता है।

लोगो मुद्रण स्विमवियर बनाने के लिए अधिक लागत बनाता है। सबसे बड़ा कारण यह है कि लोगो कितना कठिन है, मुद्रण विधि, और ब्रांडिंग के लिए किस सामग्री का उपयोग किया जाता है। ब्रांड आसान लोगो, फ्रीलांस डिजाइनरों को किराए पर लेने और एक ही बार में बहुत सारे स्विमवियर खरीद कर पैसे बचा सकते हैं। एक कुशल कस्टम स्विमवियर निर्माता चुनने से लागत कम रखने में मदद करता है और यह सुनिश्चित करता है कि स्विमवियर अच्छी गुणवत्ता है। हर मोड़ को देखना चाहिएलोगो मुद्रण विकल्पनए कपड़े पहनने से पहले। आगे की योजना स्विमवियर सस्ते रहने और अच्छी बिक्री करने में मदद करती है।

फाक

स्विमवियर के लिए सबसे किफायती लोगो प्रिंटिंग विधि क्या है?

स्क्रीन प्रिंटिंग बड़े ऑर्डर के लिए सबसे सस्ता है। यह कारखानों को कई स्विमसूट के लिए एक सेटअप का उपयोग करने देता है। यह प्रत्येक स्विमसूट की लागत कम करता है। छोटे आदेशों या विस्तृत लोगो के लिए डिजिटल प्रिंटिंग बेहतर है। लेकिन यह प्रत्येक टुकड़े के लिए अधिक खर्च करता है।

लोगो की जटिलता स्विमवियर निर्माण लागत को कैसे प्रभावित करती है?

बहुत सारे रंगों या छोटे विवरणों के साथ लोगो। प्रत्येक रंग या विवरण को अतिरिक्त सेटअप और काम की आवश्यकता होती है। सरल लोगो प्रिंट करने के लिए तेज़ और सस्ता है। ब्रांड आसान डिजाइन चुनकर पैसे बचाते हैं।

क्या ब्रांड स्विमवियर पर छपाई के लिए किसी लोगो फ़ाइल का उपयोग कर सकते हैं?

निर्माताओं को स्पष्ट, उच्च-रिज़ॉल्यूशन लोगो फ़ाइलों की आवश्यकता होती है। ये फाइलें आमतौर पर वेक्टर फाइलें होती हैं। माई, जी, या PDF धुंधली या कम गुणवत्ता वाली छवियां खराब प्रिंट बनाती हैं। ब्रांडों को सर्वोत्तम परिणामों के लिए तेज फाइलें भेजना चाहिए।

क्या ऑर्डर आकार लोगो प्रिंटिंग की कीमत को प्रभावित करता है?

हां, ऑर्डर आकार प्रत्येक स्विमसूट के लिए कीमत बदलती है। बड़े आदेश प्रत्येक टुकड़े को सस्ता बनाते हैं। कारखाने स्थापित और अधिक स्विमसूट पर काम की लागत आती है। प्रत्येक आइटम के लिए छोटे ऑर्डर की लागत अधिक है क्योंकि निर्धारित लागत समान है।

क्या स्विमवियर लोगो प्रिंटिंग के लिए अनुकूल सामग्री उपलब्ध है?

कई कारखानों में पर्यावरण के अनुकूल, जल आधारित स्याही होती है। यह ग्रह के लिए बेहतर है और लंबे समय तक रहता है। जब वे ऑर्डर करते हैं तो इन चीजों के लिए कह सकते हैं।